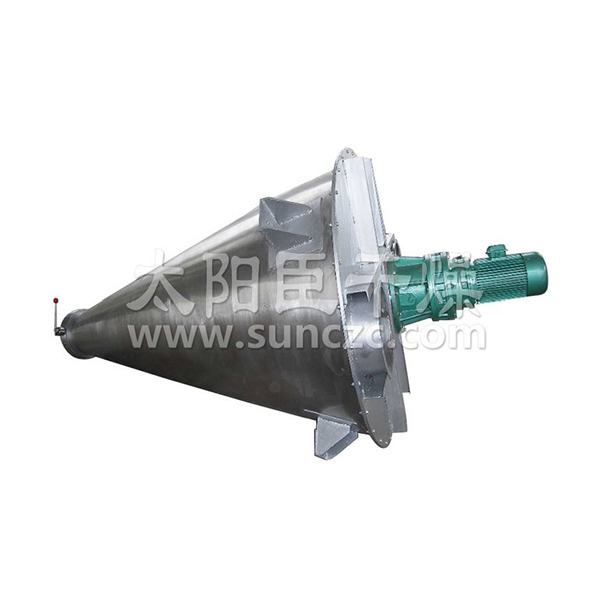

WZ series fast gravity powder mixer

Working Principle

This series of mixers features strong and efficient mixing. Two mixing wheels in the horizontal cylinder rotate at the same speed at the same speed. The specially arranged paddle ensures that the material moves radially, circularly, and axially in three directions to form a composite cycle. Achieve uniform mixing in a very short time.

Performance Features

1, high mixing accuracy, high speed, low energy consumption, sealable operation.

2, pneumatic, electric, manual discharge method.

3. An atomization device can be arranged on the cylinder cover to achieve solid-liquid mixing.

Applications

Chemicals, detergents, coatings, resins, glass silicon, pigments, pesticides, fertilizers, feed, feed additives, wheat flour, milk powder, spices, trace components, coffee, salt, additives, plastics and various slurries, powders Drying and mixing.

Technical Specifications

| Model specifications | WZ-0.05 | WZ-0.1 | WZ-0.3 | WZ-0.5 | WZ-1 | WZ-2 | WZ-3 | WZ-4 | WZ-6 |

| One time mixing kg | 24-30 | 40-60 | 120-180 | 200-300 | 400-600 | 800-1200 | 1200-1800 | 1600-2400 | 2400-3600 |

| Installed power kw | 2.2 | 3 | 4-5.5 | 5.5-7.5 | 7.5-11 | 11-15 | 18.5-22 | 22-30 | 30-37 |

| Equipment weight kg | 250 | 360 | 750 | 880 | 2100 | 2740 | 3800 | 5100 | 6200 |