Rapid Delivery for Powder Fluid Bed - FG Series Vertical Fluid Bed Dryer – TAYACN

Rapid Delivery for Powder Fluid Bed - FG Series Vertical Fluid Bed Dryer – TAYACN Detail:

FG Series Vertical Fluid Bed Dryer(FBD)

Principle

The fresh air is filtered by the two or three filters and then enter into the heating system for heating . After heated , the hot air enter into the drying chamber and blow up the material in the bowl of the FBD and let the material into fluidization conditions .during this period , the material is dried . When customer use the machine , they can set the procedure and parameters according to the process requirements , and then start the machine.

The Machine Structures

1. INLET AHU

The inlet AHU consists of Primary filter(G4), Post filter (F8), high efficiency filter(H13 )and heater with accurate temperature control. The inlet air flow, speed and pressure is variable and controllable. For the heater , it can be steam radiator ,electrical heater , gas furnace and so on .

MAIN BODY STRUCTURE

The main body structure consists of bottom bowl, movable product bowl with trolley , fluidized chamber, expansion chamber/filter housing. The bottom bowl, product container and fluidized chamber are inflatable silicon gasket sealed with compress air inspection sensor to assure the reliable sealing.

3. PRODUCT FILTER

The double structured bag filter in two pieces (in case request, stainless steel filter available) is inflatable silicon gasket sealed between the expansion chamber inner surfaces with compress air inspection sensor to assure the reliable sealing. A dust sensor is mounted on the exhaust piping and interlocked from control sys to secure the product safety during processing stage.

4. EXHAUST AHU

The exhaust dust collection filter is optionally designed for protect environment.

Features

1. Fluidized bed to realize rapid heat transfer of medium.

2. Sealing negative pressure operation, no dust.

3. Since anti-static materials are used as filters, the operation is safe;

4. The equipment has no dead angle, which is convenient for comprehensive cleaning and no cross contamination;

5. Comply with GMP requirements.

6. HMI and PLC control system, motor speed is controlled by VFD, and all process parameters can be recorded.

Overall drawing (Through-wall structure)

Process Chart

Application

The machine is main used for drying powder or granules from pharmaceutical, foodstuff, chemical and so on industries.

Optional Item

1.2Bar &10Bar POWDER EXPLOSION

The 2bar and 10 bar powder explosion proof design is selectable to ensure the operator, equipment and environment safety with reliable grounding device.

2. Product charging by the lifting machine

3.Product charging by the vacuum transfer machine

4.Through-wall structure for the machine in on request.

Technical Parameters

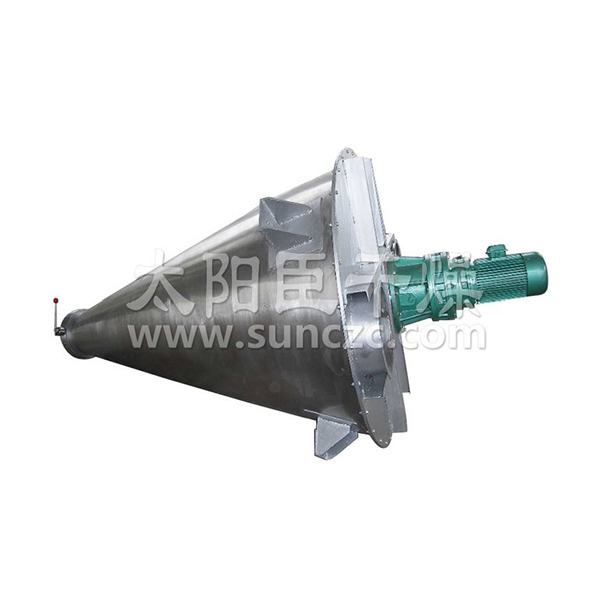

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Rapid Delivery for Powder Fluid Bed - FG Series Vertical Fluid Bed Dryer – TAYACN , The product will supply to all over the world, such as: Macedonia, Bandung, Riyadh, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.