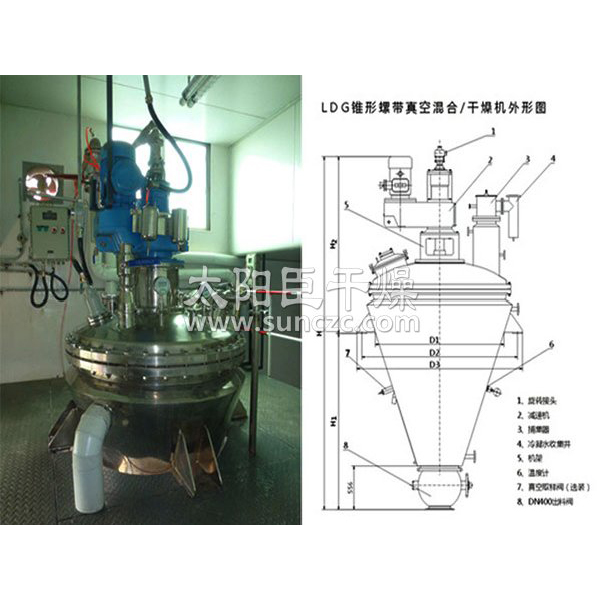

Low price for Conical spiral belt vacuum dryer - LDG Series Conical spiral belt vacuum dryer – TAYACN

Low price for Conical spiral belt vacuum dryer - LDG Series Conical spiral belt vacuum dryer – TAYACN Detail:

Specification

500L 1000L 1500L 2000L 3000L 4000L 5000L 8000L

Multipurpose

Conical spiral belt vacuum mixer / dryer can be applied in many fields, especially suitable for process treatment in closed and controllable environment, such as pharmaceutical and chemical industry, additives, unstable extract crystals in air or high temperature and various pharmaceutical and biological processes. The multi-purpose conical spiral belt vacuum mixer / dryer equipment of sunchen company is an ideal choice to meet your production needs.

High Efficiency Vacuum Drying

Conical spiral belt vacuum mixer / dryer is a multifunctional equipment integrating mixing, drying and distillation. It adopts fully closed GMP cleaning design. Its drying efficiency is 3-5 times that of the same specification (double cone rotary vacuum dryer), the charging amount is 2 times that of (double cone rotary vacuum dryer), and the relative efficiency is improved by 6-10 times. The spiral belt agitator can make the mixing effect of material spiral circulation from bottom to top in advance, and can obtain efficient heat transfer characteristics. When the material filling rate works at 30% – 100%, it can obtain the utilization efficiency of 100% heating area. It is a new type of drying equipment with energy saving, high efficiency, environmental protection and cleaning.

High Mixing Accuracy

High mixing accuracy can be achieved. Even if materials with different densities and particle shapes are mixed in the same batch of products, the required mixing accuracy can be achieved in the conical mixer. Under such harsh process conditions as adding a small amount of materials to a large number of materials, it can also be mixed in the conical spiral belt vacuum mixer / dryer of taiyangchen company.

Low Shear Force; Ribbon Stirring

The spiral belt agitator with low shear force is used to gently mix materials under low speed energy consumption. The mixing intensity and mixing time are low.

Applicable To Viscous Materials

Under the action of friction and pressure generated between material particles during mixing, even materials with strong viscosity can be separated and mixed effectively.

Different Material Loading Rates

The filling rate of the conical spiral belt vacuum mixer / dryer is 30% – 100% of the effective working volume. Within this range, the mixing and drying of different loading quantities can obtain consistent results.

Seal Cleaning Design

The conical spiral belt vacuum mixer / dryer itself is a fully closed design, and all connecting parts, including feeding and discharging, are fixed, which can meet the safety requirements of materials and environment.

Large Diameter Ball Interface Discharge Valve

● Real spherical valve.

● Powder, liquid and gas seal.

● Eccentric shaft structure, no friction on sealing surface.

● Unobstructed, all open in the diameter direction.

● Hygienic and GMP standard design, no dead zone, no residual materials, easy to clean.

● The standard materials of the structure are SUS316 and SUS304 stainless steel.

● The structure has no cast parts, and there are no pores and shrinkage defects.

● Closed bearing chamber.

● Standard surface treatment, internal Ra0 four μ m. External Ra0 eight μ m.

● Designed for full vacuum and 0.25MPa pressure.

● The design can be filled with nitrogen, which is conducive to vacuum drying and eliminating mixing dead angle.

● The design can be filled with cleaning fluid to clean the inside of the valve body.

● Filter can be installed in the design to prevent dust discharge during discharging.

Vacuum Sampling Valve

The vacuum sampling valve is directly connected with the conical vacuum dryer heated in the spiral belt, without any dead angle, so as to avoid the pollution of the sampling sample. The sampling valve has a large working pressure of 0.8MPa, full vacuum and a working temperature of 150 ℃.

Technical Specifications

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Low price for Conical spiral belt vacuum dryer - LDG Series Conical spiral belt vacuum dryer – TAYACN , The product will supply to all over the world, such as: Nepal, Burundi, Denver, Our company will continue to adhere to the superior quality, reputable, the user first principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!