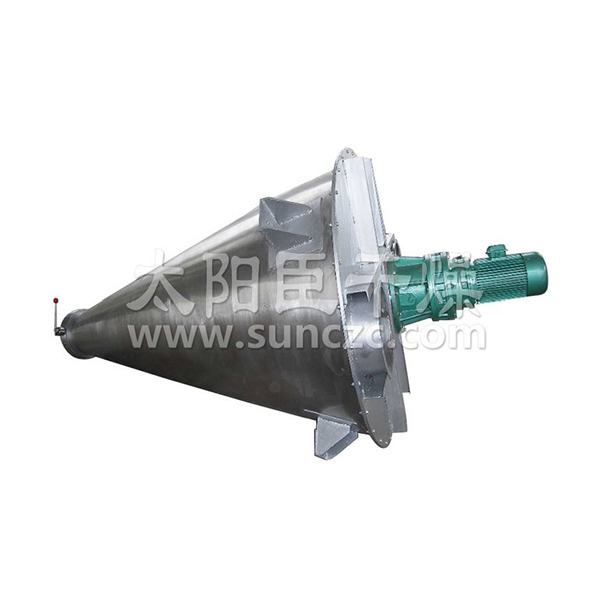

Cheap PriceList for Blender Vertical - DSH series double spiral cone mixer – TAYACN

Cheap PriceList for Blender Vertical - DSH series double spiral cone mixer – TAYACN Detail:

Product Overview

Thespiral and the rotation of the material cause the material to generate compound motion in the cone. It mainly produces four types of motion:

1. The spiral orbits the wall to make the material move in a circular motion along the cone wall;

2. The spiral rotates the material from the bottom of the cone. Spiral rise;

3. The male and female composite movement of the spiral causes a part of the material to be absorbed into the cylindrical surface of the spiral while being subjected to the centrifugal force of the spiral rotation to discharge a part of the material in the cylindrical surface of the spiral toward the cone;

4. The rising material is subject to Decrease in gravity. The four types of motion create convection, shear, and diffusion in the mixer to achieve rapid and uniform mixing.

Product Features

◎ can be equipped with flying knife, spray atomization assembly, to meet the special process requirements.

◎Feeding valve has manual and pneumatic two ways.

◎Special materials can increase the motor power (increasing).

The Products Are Applied

In powders and powders (solid-solid) such as chemicals, medicines, pesticides, dyes, petroleum, metallurgy, building materials, powders and liquids (solid-liquid), liquids and liquids (liquid-liquid), and reactions. Dry and cool.

Technical Specifications

| model | unit | DSH0.3 | DSH0.5 | DSH1 | DSH2 | DSH4 | DSH6 | DSH10 |

| Full volume | (m 3 ) | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| Loading factor | 0.4-0.6 | |||||||

| Mixture material size | (um)40-3000 | |||||||

| Working conditions | Normal temperature, atmospheric pressure, dust seal | |||||||

| Each production | (kg) | 180 | 300 | 600 | 1200 | 2400 | 3600 | 6000 |

| power | (kw) | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 20.7 | 30.7 |

| Mixing time | (min) 4-10 (special material determined by test) | |||||||

| Total Weight | (kg) | 500 | 1,000 | 1200 | 1500 | 2800 | 3500 | 4500 |

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation is our enterprise philosophy which is regularly observed and pursued by our firm for Cheap PriceList for Blender Vertical - DSH series double spiral cone mixer – TAYACN , The product will supply to all over the world, such as: Porto, Germany, Japan, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!